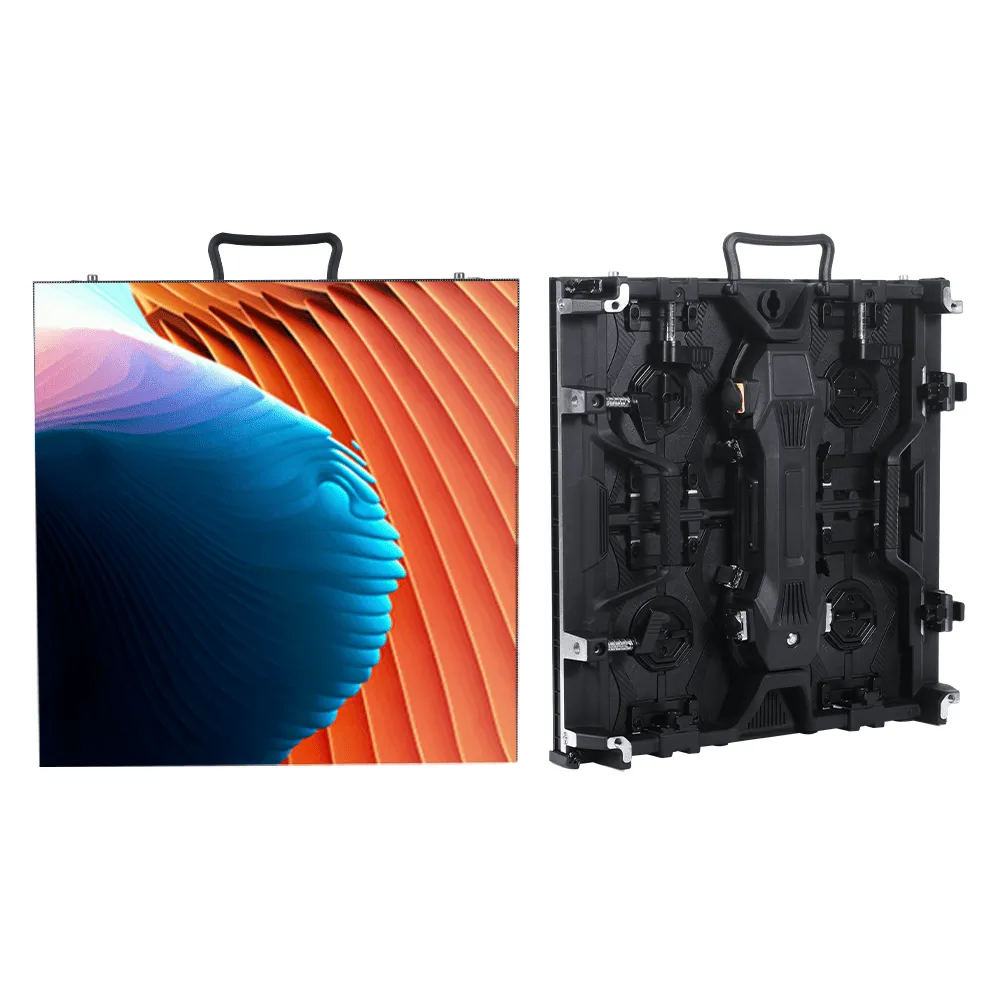

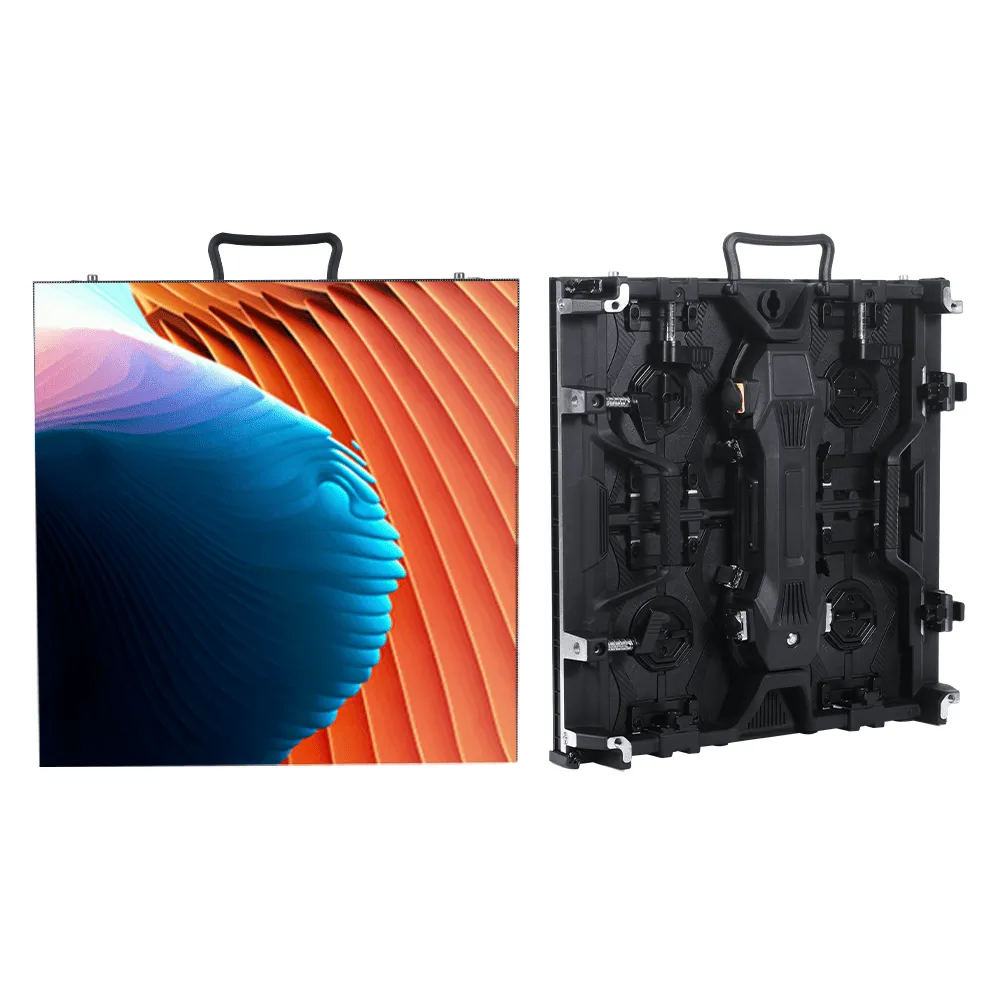

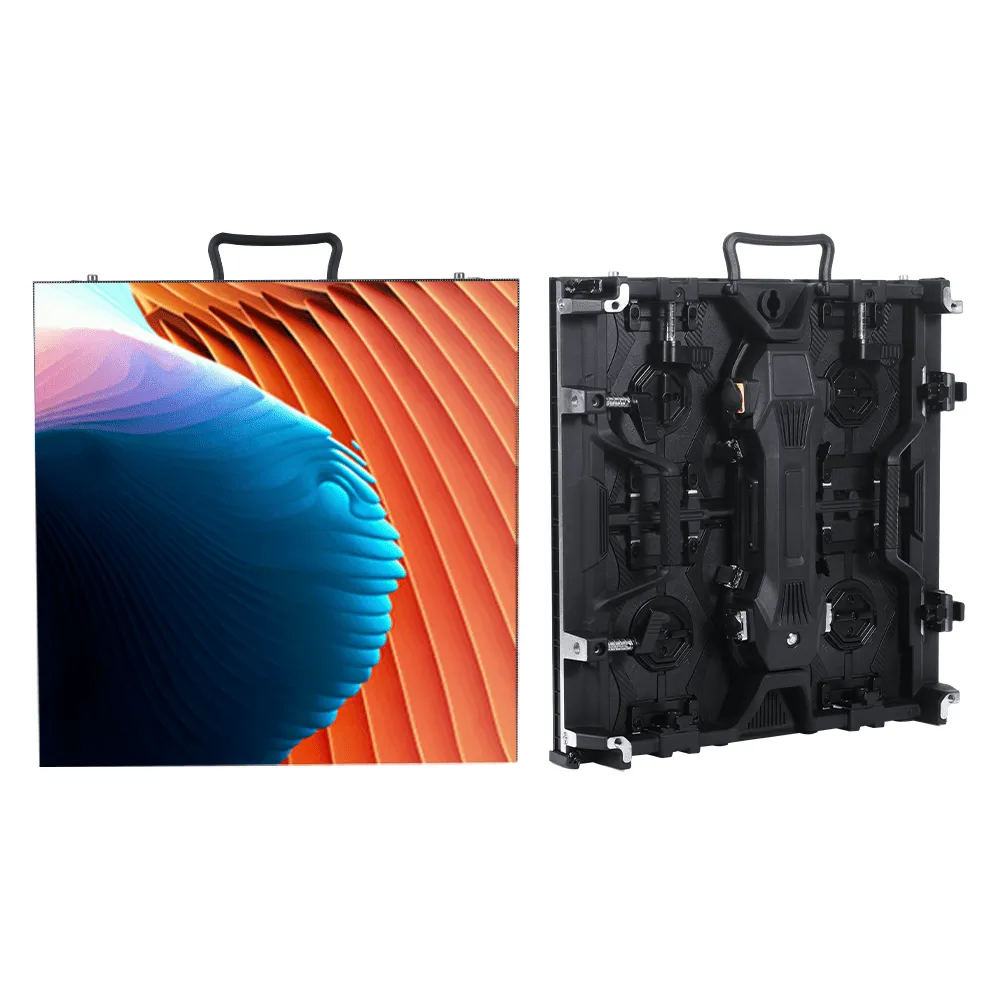

Our cob led screen (Chip-on-Board) technology redefines reliability for mission-critical displays. By embedding microchips directly into substrates—eliminating fragile solder joints—we deliver unmatched performance where traditional SMD LEDs fail.

Why COB Outperforms SMD:

Near-Zero Pixel Failure: Patented encapsulation prevents 99.9% of dead pixels

Military Resilience: IP54-rated against dust/moisture/impact (tested to MIL-STD-810G)

True Seamless Canvas: No visible grid lines at any viewing angle

Glare Reduction: Specialized surface coating reduces reflection of 65%