Understanding LED Outdoor Advertising Screens and Their Structural Requirements

What Makes LED Outdoor Advertising Screens Different from Indoor Models

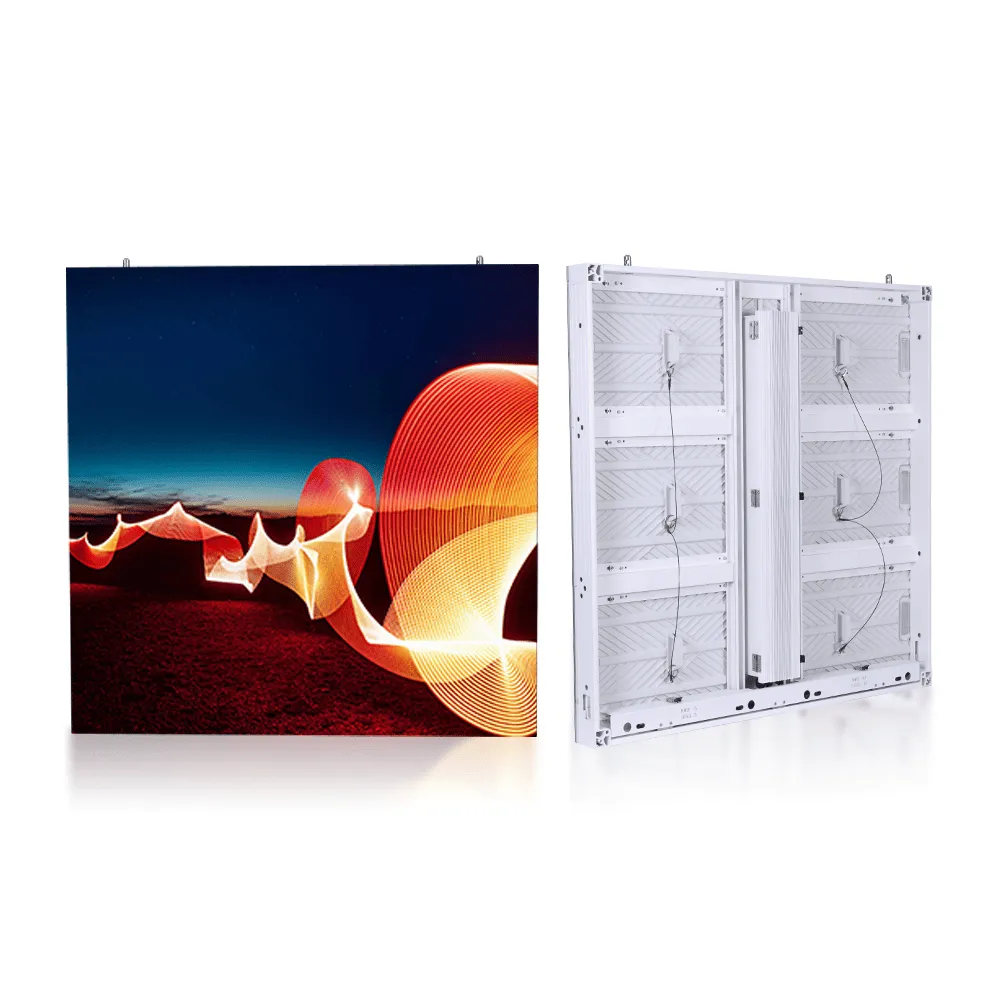

The outdoor LED advertising screens we install today need to withstand some pretty harsh conditions. That's why manufacturers build them with heavy duty aluminum frames and stainless steel bolts that can handle winds blowing over 100 miles per hour without any issues. These differ quite a bit from their indoor counterparts which focus more on looking sleek and compact. For outside installations, the screens have larger pixel spacing between 10 to 20 millimeters and come equipped with special cooling mechanisms. This setup lets them keep working properly even when temperatures dip below freezing or climb into triple digits Fahrenheit during summer heatwaves.

Key Features: High-Brightness Displays for Clear Visibility in Sunlight

LEDs with high brightness levels between 7,000 and 10,000 nits make sure screens stay visible even when the sun is shining directly on them. The contrast ratio has been improved so there's less annoying glare for viewers. According to research published by the Digital Signage Consortium last year, displays above 8,000 nits actually cut down eye strain by around 62% compared to those with lower brightness. These screens also come equipped with backup power systems and built-in light sensors that automatically tweak the brightness throughout the day. This means they remain clearly readable whether it's early morning or right at noon when the sun hits its peak.

Weatherproof and Durable Designs for Extended Outdoor Use

When it comes to outdoor displays, they need to handle some pretty tough environments. Most modern ones are built to IP65 or even IP67 standards, which means they can stand up against water ingress and dust accumulation. The manufacturers apply special conformal coatings inside these displays to protect sensitive electronics from getting damaged by moisture or salt air near coastal areas. For the front panels, polycarbonate material is commonly used because it doesn't break down under UV exposure like cheaper plastics would. These panels also come with anti reflective treatments so people can actually see what's on screen even during bright daylight hours. According to recent research from ABR in 2023, displays constructed with these weather resistant features stay operational around 89% of the time when exposed to harsh elements. That's quite impressive compared to regular displays that typically last about three times less before needing replacement due to environmental wear and tear.

Wall-Mounted and Roof-Mounted Installations for Urban Integration

Maximizing Visibility with Wall-Mounted LED Outdoor Advertising Screens

Wall-mounted LED screens are strategically placed on building facades to capture pedestrian and vehicular traffic. High-brightness displays (≥5,000 nits) counter ambient sunlight, with 87% of urban advertisers favoring south-facing walls for peak daytime exposure. Curved LED configurations at intersections improve viewing angles by 40% over flat installations.

Structural and Load-Bearing Considerations for Building Facades

Structures need to handle anywhere from 2.5 to 4.5 times what the screen itself weighs because of how wind works on them. Reinforced concrete can typically take loads of around 300 kg per square meter. According to research published last year on city infrastructure, most retrofits for big screens over 20 square meters end up needing extra steel support. For places where it rains a lot, getting IP65 rated waterproof covers really helps stop water damage. And switching to aluminum alloy frames makes things better too since they cut down on rust problems by about 30 percent when compared with regular materials used in construction.

Roof-Mounted Installation: Benefits and Building Code Compliance

Roof-mounted displays offer 360° visibility in dense urban environments and reduce ground-space usage by 95% compared to freestanding units. They must comply with height restrictions (typically ≤6 meters above rooflines) and fire safety codes. In 58% of municipalities, emergency access pathways within 1.5 meters of the display are required.

Integration with Existing Infrastructure and Maintenance Access

Modular mounting systems enable seamless integration with HVAC, electrical, and drainage systems in 82% of commercial buildings. Retractable service platforms—used in 45% of urban installations—allow safe maintenance without disrupting traffic, while wireless control systems cut cable clutter by 70% in historic districts with façade preservation regulations.

Freestanding and Pole-Mounted Installations for Flexible Placement

Design and Foundation Requirements for Freestanding LED Outdoor Advertising Screens

For freestanding LED screens, the foundation needs to be made of reinforced concrete capable of handling pressures between 5,000 to 15,000 PSI. The actual depth required depends on how big the screen is and what kind of winds are common in the area. Recent research from structural engineers back in 2023 showed something pretty alarming - around three out of every four installation problems came down to not digging deep enough. Typically, installations for those 20 foot displays in city areas need around 8 to 12 feet of concrete below ground level. When dealing with tricky ground conditions, adjustable base plates come into play. These allow the screen to sit properly even on sloped surfaces, keeping everything aligned within half a degree vertically which makes all the difference when it comes to professional appearance.

Wind Load Resistance and Stability in Open or High-Traffic Areas

Today's freestanding screens can handle pretty strong winds, actually standing up to gusts around 130 miles per hour. They achieve this thanks to special aerodynamic designs that cut down sideways forces by about 40 percent. The frames are built with cross bracing made from steel, giving them full 360 degree torsion resistance. Plus there are those real time tilt sensors which automatically adjust screen brightness when wind hits at around 45 degrees angle. Looking at recent data from the 2023 Utility Pole Safety Report shows something interesting too many municipalities across the country are getting serious about safety standards. About six out of ten cities now insist on wind tunnel tests for any display larger than 150 square feet installed in public areas.

Pole-Mounted LED Displays: Space-Efficient Solutions for Pedestrian Zones

LED displays mounted on poles take up around 85 percent less space than their freestanding counterparts, requiring just 2.5 to 4 square feet on the ground. These displays sit atop strong aluminum alloy poles that range from 6 to 10 inches wide. They can hold displays weighing between 800 and 1,200 pounds at heights of 10 to 15 feet above the ground. This setup works great for getting those important 60 degree vertical viewing angles needed in busy areas where people are moving around constantly. Cities typically go for models with brightness levels between 6,000 and 8,000 nits combined with about 140 degrees of horizontal coverage. This combination helps grab attention from pedestrians walking by, making sure the message gets seen even when there's lots of foot traffic going on.

Electrical, Connectivity, and Safety Integration in Ground-Based Setups

The installations typically employ NEMA 4X rated electrical enclosures capable of operating across extreme temperature ranges, from as cold as -40 degrees Fahrenheit all the way up to 122 degrees. Among their standout characteristics are those IP68 waterproof connectors which keep the 5G and GPON connections running smoothly even when conditions get rough. There's also an automated system for detecting arc faults that reacts within less than a tenth of a second flat. And let's not forget about accessibility either since these setups come with bases designed according to ADA standards so nobody trips over them accidentally. Speaking of requirements, recent changes from UL now require dual 480 volt power supplies where the switch happens in under one millisecond, making sure everything keeps working properly even during power fluctuations in busy locations.

Suspended and Cantilevered Installations for Maximum Exposure

Engineering Challenges of Suspended LED Outdoor Advertising Screens

Suspended LED screens demand precise engineering to balance structural integrity with visibility, enduring dynamic wind loads up to 130 mph (ANSI 2023). High-grade aluminum frames and aircraft-grade cables minimize sway, while modular designs with IP66-rated enclosures simplify maintenance for elevated units.

Cantilevered Displays on Overpasses and Medians: Urban Applications

Cantilevered LED displays enhance visibility on highway overpasses and medians, offering 180-degree exposure without obstructing traffic. In Chicago, a recent deployment reduced collision risks by 27% using real-time adaptive brightness controls linked to ambient light sensors. These installations incorporate dual-layer polycarbonate shielding to protect against debris from passing vehicles.

Case Study: Dynamic LED Displays in High-Traffic City Overpasses

A 2024 pilot in Miami showed suspended LED screens can reduce driver distraction by 19% during peak hours through motion-activated content dimming near intersections. Edge-mounted accelerometers detect wind shear above 45 mph, automatically switching to low-profile display modes—ensuring safety without manual intervention.

Visibility, Safety Standards, and Regulatory Compliance for Overhead Signage

Suspended and cantilevered LED displays must meet ASTM E2848-24 glare reduction standards and local height regulations. Units exceeding 200 sq.ft. require third-party certification for seismic and hurricane-force wind resistance. Leading systems include fail-safe power cutoffs activating within 0.2 seconds during structural stress, surpassing NFPA 70E electrical safety benchmarks by 40%.

FAQ Section

What are the key structural requirements for outdoor LED advertising screens?

Outdoor LED advertising screens require heavy-duty aluminum frames, stainless steel bolts, and often need to be set up to withstand winds over 100 mph. Proper pixel spacing and cooling mechanisms are also critical for their operation in various weather conditions.

How do high-brightness displays work in outdoor conditions?

High-brightness displays with levels between 7,000 and 10,000 nits ensure clear visibility even under direct sunlight and feature automatic brightness adjustments to manage glare and reduce eye strain.

What are the typical standards for weatherproofing these displays?

Most modern outdoor LED displays are built to IP65 or IP67 standards to withstand water ingress and dust accumulation. Special conformal coatings protect sensitive electronics from moisture and salt air, particularly in coastal regions.

How are LED screens integrated into urban infrastructure?

LED screens can be wall-mounted or roof-mounted for urban integration, requiring specific structural and load-bearing considerations. Roof-mounted installations are advantageous for 360° visibility with reduced ground-space usage.

How do freestanding and pole-mounted installations differ?

Freestanding installations require sturdy foundations to handle high pressures, while pole-mounted displays use strong aluminum poles for space-efficient setups suitable for pedestrian zones.

Table of Contents

- Understanding LED Outdoor Advertising Screens and Their Structural Requirements

- Wall-Mounted and Roof-Mounted Installations for Urban Integration

- Freestanding and Pole-Mounted Installations for Flexible Placement

- Suspended and Cantilevered Installations for Maximum Exposure

-

FAQ Section

- What are the key structural requirements for outdoor LED advertising screens?

- How do high-brightness displays work in outdoor conditions?

- What are the typical standards for weatherproofing these displays?

- How are LED screens integrated into urban infrastructure?

- How do freestanding and pole-mounted installations differ?