COB Packaging Innovations by HXTECH LED Panel Manufacturers

Core Principles of Chip-on-Board Technology

chip on board (COB) technology, introduces direct mounting of the LED chips to the printed circuit board (PCB) for both aesthetic appeal and capability. This direct bonding technique eliminates the need for wire bonding and the individual lamp bead encapsulation methods, and provides a uniform epoxy resin together, and sealed. The monolithic approach optically and thermally couples the silicon readout to the chip that increases thermal conductivity up to 40%, leading to pixel pitches smaller than 0.7mm crucial for ultra-high-resolution displays. Skirting the reflow soldering process, COB minimizes failure points and maximizes mechanical robustness where high-quality visuals are required.

Enhanced Durability Through COB Packaging

The uniform of COB encapsulant has excellent anti-mold ability, and it is IP54 that is dustproof, waterproof and UV resistant and good in protection from drop and prevents from static electricity without distortion. This one-piece sealing eliminates damage at pixel-level due to cleaning, or high traffic touch, and ensure optical homogeneity. COB packaging displays have shown in accelerated stress testing 30% longer operational life than traditional ones. The non-porous surface is free of cracks, smooth and easy to clean further reducing maintenance requirements for public facilities such as transport hubs, hospitals and surgeries.

Case Study: COB in Commercial Display Solutions

The headquarters of a global financial institution The trading floors of this multinational financial institution access different COB based video walls. In the outdoor setting, these 24/7 displays achieved uniform color calibration even under punishing sunlight and withstood multiple direct hits to the surface. Across more than a year, the solution achieved 99.98 percent availability and zero pixel failures, consistently exceeding alternative display technologies that required maintenance every month. The project validated that COB works in mission-critical applications where high reliability and continuous operation are required.

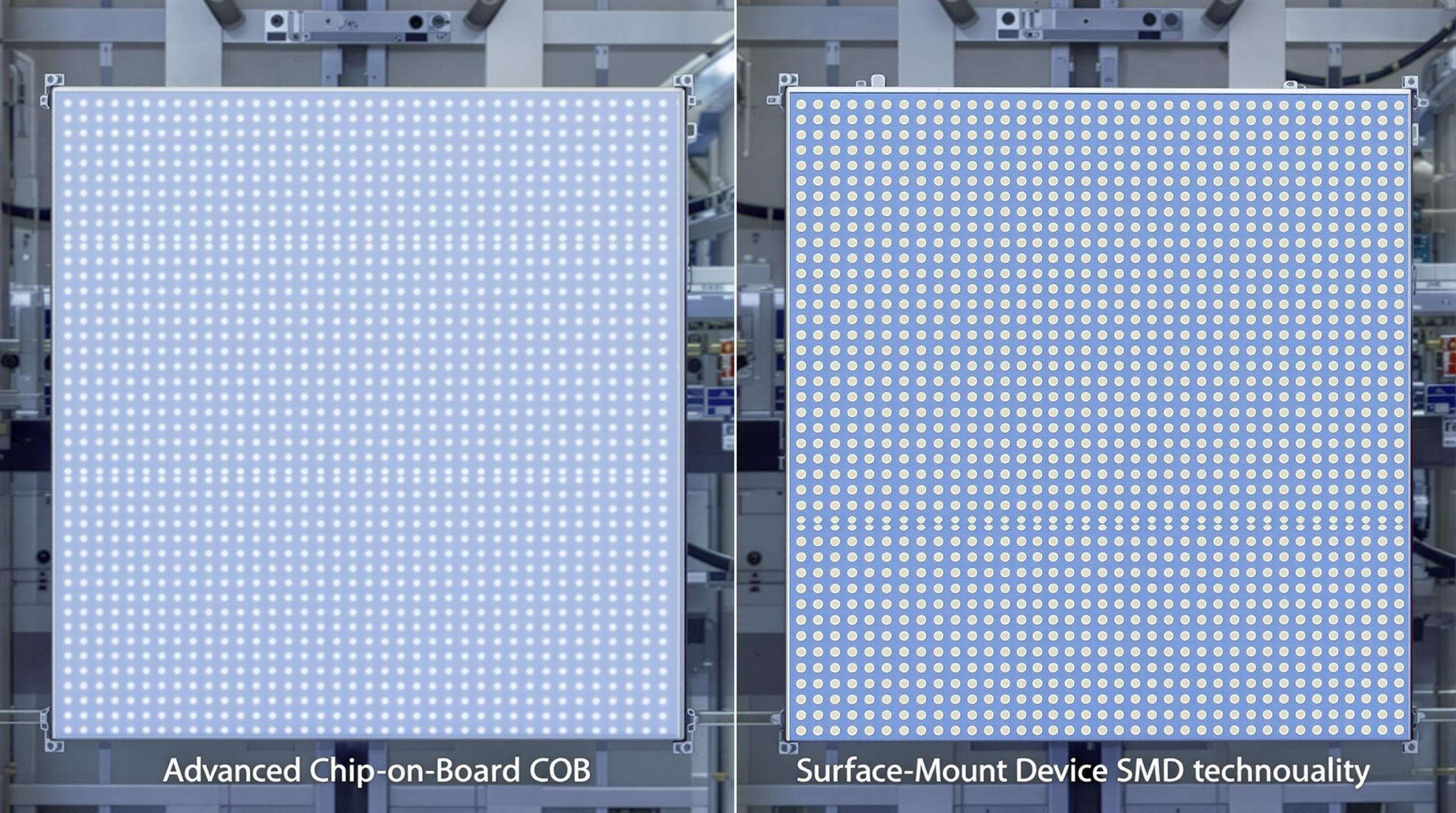

Performance Comparison: COB vs SMD Technology

| Characteristic | COB Technology | Traditional SMD |

|---|---|---|

| Pixel Pitch | < 0.7mm achievable | Limited to ≥0.9mm |

| Failure Rate | 0.02% at 1000h (2023) | 0.3% at 1000h |

| Thermal Resistance | 3.5°C/W | 8.2°C/W |

| Impact Resistance | Withstands 5J force | Fails at 2J force |

| Environmental Seal | Full IP54 encapsulation | Point-specific sealing |

Unlike traditional Surface-Mount Device (SMD) options that require Individually Encapsulated LEDs, COB delivers higher pixel density and greater structural integrity. COB has 15× more shock resistance and is free from SMD failure modes such as gold wire breakage. These are the features that make COB the ideal answer for costly display applications. COB superiority for intensive-use cases with higher durability demands is confirmed by industry assessments such as forthcoming display technology reviews. The cost of manufacturing an SMD is still much lower for commodity displays, but COB offers much better life value when looking at premium sectors.

Micro and Mini LED Technologies at HXTECH LED Panel Manufacturers

Micro and Mini LED technologies represent the pinnacle of display innovation, transforming commercial visuals through unprecedented pixel density and power efficiency. Leading manufacturers refine these approaches to redefine visual experiences across diverse sectors. The progression toward standardized definitions optimizes technological integration while balancing optical performance with cost parameters.

Defining Micro-LED Industry Standards

Industry standards classify Micro-LEDs by chip dimensions under 100 micrometers, enabling pixel densities exceeding conventional displays. Establishing uniformity involves comprehensive criteria addressing luminance uniformity, color consistency, and defect tolerance thresholds. Recent advancements at major tech events feature sub-0.2-inch modules, setting benchmarks for future integrations.

MIP (Mini LED in Package) Implementation Strategies

MIP technology mitigates Mini-LED integration hurdles by packaging chips before placement, enhancing assembly precision. Key tactics include selective redundancy designs to overcome yield limitations and hybrid substrate solutions optimizing thermal dissipation. This approach accelerates scalable manufacturing by streamlining pixel-level defect correction.

Commercial Applications of Micro-LED Video Walls

Top commercial venues are increasingly using Micro LED video walls for superior resolution in immersive displays and dynamic retail settings. These displays have 200% higher contrast ratio than old LCD models which maintains contrast in light or dark environments. Showcase at major electronics conferences the novelty of such devices in realising next-generation interactive mirror displays capturing emerging applications for smart retail interfaces.

Cost-Efficiency in Mini-LED Production

Mini-LED production cost reduction centers on yield optimization via modular driver circuits and standardized transfer protocols. Closed-loop material recovery during manufacturing cuts waste by 37%, while simplified testing protocols reduce per-unit validation expenses. These methodologies bridge premium performance and mainstream market accessibility.

Energy Efficiency Breakthroughs from HXTECH LED Panel Manufacturers

HXTECH LED panel manufacturers are driving the next wave of energy-efficient lighting solutions through groundbreaking thermal management and renewable energy integration. By addressing heat dissipation challenges and leveraging solar technology, these innovations reduce operational costs while aligning with global sustainability goals.

Advanced Thermal Management Systems

New age LED panels produce 40% less waste heat as compared to older generation panels, yet efficient thermal management is essential for energy optimization. Best-in-class products utilize liquid-cooled heat sinks or phase-change materials that help maintain optimal temperatures under 45°C to prevent lumen degradation, extending product lifetime by up to 30% versus other thermal solutions. The resultant lower level of energy required for cooling of the product corresponds to reported 18-22% lower overall power consumption in commercial end products.

Solar-Powered LED Panel Integration

Progressive producers already include photovoltaic cells within panel housings, meaning that self-powered lighting systems which produce a yield of 150-200 W/m² of light is being harvested using natural daylight. Dual mode function lets light automatically runs on low light mode(30% power) as constant light for first 5Hrs only when place at outdoor, switch to full (100%) lighting mode for 30secs-1min, when motion detected for high illumination, lighting up for 30secs-1min, and back to low light mode when motion goes away. Achieve 70-90% saving energy for ORC365, for solar, outdoor installation. Used in combination with intelligent charge controllers, these hybrid systems eliminate the necessity for external battery banks and ensure reliable constant light intensity. Early adopters estimate 60% less to spend on energy alone with large video walls, and sub-three year return on investment in sunbelt states.

Smart Control Systems by HXTECH LED Panel Manufacturers

IoT-Enabled Lighting Customization

Today’s IoT-based lighting systems provide the user with the ability to adjust color temperature and brightness using mobile applications or voice commands. These work in concert with building management systems to develop dynamic scenes that respond to a range of events—from enlivening workspace productivity, to creating settings in hospitality environments. State-of-the-art control algorithms continuously (and autonomously) adapt illuminance to occupancy and available natural light by deliberate tuning to minimize energy consumption and ensure visual comfort without any manual settings.

Real-Time Energy Consumption Monitoring

On-board monitoring solutions offer detailed visibility of power consumption on a per LED/luminaire basis or throughout an entire installation. Through centralized dashboards, site managers can view real-time consumption data to quickly spot issues such as overuse of lighting and/or inappropriate light fixtures. Smart sensing also reduces energy waste in businesses by 34%, and that’s just for commercially operated buildings, working hand in hand with automated load-balancing protocols (source: 2025 Intelligent Battery Sensor Market Report). This visibility optimizes data-driven maintenance planning and can help organizations achieve sustainability goals.

Sustainable Practices in HXTECH LED Panel Manufacturing

Eco-Friendly Material Selection Criteria

Green when you see our LED Vision Panels Leading LED panel manufacturers are also focused on low impact materials with 95% of components being recyclable. Requirements involve exclusion of heavy metals such as lead and mercury, use of halogen free polymers, and minimizing use of rare earth elements. RoHS (Restriction of Hazardous Substances) and EPEAT® certified to meet global sustainability standard. High-grade encapsulation resins are used to improve the lifespan of the products by up to 30 percent. Such methods of making reduce generation of toxic waste, and offer optical efficiency greater than 150 lm/W in state of the art modern LED's.

Closed-Loop Recycling Processes

Leading manufacturers attain 97% recycling rate using closed-loop systems that recycle end-of-life panels. The aluminum heat sinks and PCBs are mechanically separated and smelted for use in new fixtures. The company’s chemical treatments remove 99.9% pure gallium nitride from discarded chips. Partnerships with e-waste recyclers licensed through Basel Action Network Ltd. help ensure proper handling of the trace semiconductors and plastics. These processes, which incorporate 40% post-industrial waste, cut COâ€â„¢ emissions 18 metric tons per plant per year.

Advanced Display Solutions by HXTECH LED Panel Manufacturers

Flexible LED Panels for Architectural Integration

Curvable LED panels can integrate into architecture like never before, with the ability to bend to surfaces with only a 500mm curve in any XY directioN: With ultra-thin, conformable substrates and protective polymer encapsulation, these displays can be made to ensure uniform brightness through dynamic installations. Architects take advantage of this flexibility for wrap-around building faÃ’ades, undulating interior elements, and kinetic art installations where conventional panels couldn’t cope. The technology can also survive cycle bending with no pixel degradation, proven by outdoor installations subjected to seasonal thermal cycles. These products turn physical constraints into creative possibilities and remain durable enough for commercial spaces.

Glasses-Free 3D Display Innovations

Glasses-free 3D technology achieves a sense of depth and realism by utilizing a highly-engineered lenticular lens to deliver an image to each eye. Unlike traditional displays, these systems display different parallax images to observers. Sub-1. 0mm) completely remove viewing angle limits for public displays and commercial installations. Energy-Efficient Processing Chips can convert standard 2D material into 3D, real-time outputting the content while preserving high-level brightness (up to 3000 nits). Existing applications include interactive retail displays, museum exhibits, as well as interactive control rooms where user experience is enhanced through intuitive data visualization.

FAQs

What is COB technology?

COB (Chip on Board) technology involves directly mounting LED chips to the printed circuit board, eliminating the need for traditional wire bonding.

How does COB compare to SMD technology?

COB technology offers lower failure rates, higher thermal resistance, and better impact resistance than traditional SMD technology.

What are the sustainability practices in LED panel manufacturing?

Sustainable practices include using eco-friendly materials, closed-loop recycling processes, and achieving high recycling rates for end-of-life panels.

Table of Contents

- COB Packaging Innovations by HXTECH LED Panel Manufacturers

- Micro and Mini LED Technologies at HXTECH LED Panel Manufacturers

- Energy Efficiency Breakthroughs from HXTECH LED Panel Manufacturers

- Smart Control Systems by HXTECH LED Panel Manufacturers

- Sustainable Practices in HXTECH LED Panel Manufacturing

- Advanced Display Solutions by HXTECH LED Panel Manufacturers

- FAQs