Clean Large LED Screen Panels Regularly to Maintain Clarity and Performance

Use a soft, lint-free cloth to clean large LED screen panels safely

The right microfiber cloth can take away about 98% of those pesky surface particles without harming sensitive LED parts. When cleaning, go slow and move in circles while making sure the panel isn't turned on, and don't press too hard so we don't damage those tiny solder connections. Paper towels are out of the question here, same goes for anything abrasive since they tend to scratch surfaces just enough to mess with how light spreads across them. If there's something really stuck on, a quick dip in distilled water works wonders, but be careful not to get things too wet because extra moisture actually speeds up corrosion in connector areas over time.

Avoid harsh chemicals when cleaning LED screens with proper materials

Mixing isopropyl alcohol with distilled water at around 70% concentration works pretty well for getting rid of grime without messing up those anti-glare coatings on screens. Strong stuff like ammonia or acetone tends to eat away at protective layers much quicker than we'd like. Some recent testing showed these harsh chemicals can actually speed up deterioration by about threefold, which means displays start turning yellow way before they should. A good practice everyone should follow? Spray whatever cleaning solution onto a microfiber cloth first instead of applying it straight to the screen itself. This helps avoid any unwanted liquid sneaking into those tiny pixel areas where it definitely doesn't belong.

Establish a routine cleaning schedule to prevent dust and humidity buildup

The frequency of cleaning industrial displays really depends on where they're installed. Displays located in busy spots need cleaning every two weeks approximately, whereas those in more controlled settings can usually wait about a month between cleanings. According to some research published in 2025, displays cleaned only once every three months showed their brightness dropping off much quicker than others, around 40% faster actually, because dust builds up and conducts electricity over time. When doing maintenance work, it's also important to check the humidity levels regularly. If the air stays consistently above 60% relative humidity, there's a noticeable jump in short circuit problems, about 18% higher risk according to the same study, particularly for those big displays with lots of connectors.

Optimize Brightness and Display Settings to Extend LED Panel Lifespan

Proper calibration of brightness and display settings is critical for maximizing the operational lifespan of large LED screen panels. These systems consume significant energy and experience accelerated wear when pushed to extreme limits, making balanced adjustments essential.

Adjust Brightness Based on Ambient Environment to Reduce Strain and Energy Consumption

According to research published in 2023 on display tech, cutting screen brightness down by around 30 percent indoors actually saves about 18% on power usage without making things hard to see. When it comes to displays outside, the trick is to crank up the brightness just when sunlight is strongest to fight off glare, then let them fade back down as evening rolls in. What this does is keep those LED modules from getting too hot, which matters because excessive heat really eats away at components over time. Most technicians will tell you that managing temperature is one of the biggest challenges in keeping outdoor screens running smoothly for years.

Minimize Direct Sunlight and UV Exposure During Daylight Operation

UV radiation accelerates color fading and material brittleness in large LED screen panels. Install angled shading structures or anti-glare films on outdoor displays to deflect sunlight without blocking visibility. For semi-outdoor installations, consider UV-filtering protective layers that block 92% of harmful wavelengths while preserving image clarity.

Prevent Pixel Degradation with Balanced Display Settings and Usage Patterns

Avoid prolonged static imagery (e.g., logos) beyond four hours to prevent uneven pixel aging. Implement these practices:

| Setting | Recommendation | Impact on Lifespan |

|---|---|---|

| Color Temperature | Maintain below 6500K | Reduces blue LED stress |

| Contrast Ratio | Keep below 70:1 for 16h/day use | Prevents driver overload |

| Refresh Rate | Set ≥ 3840Hz for video content | Minimizes ghosting |

Program content rotation schedules to distribute wear evenly across display zones, particularly for large-format installations.

Ensure Proper Ventilation and Temperature Control to Prevent Overheating

Maintain Adequate Airflow and Clearance Around Large LED Screen Panels

LED screens get pretty hot when they're running, which means good airflow really matters for their performance. According to industry research published last year in the Digital Display Report, panels that don't have enough ventilation tend to last about 40% less time than properly cooled ones. Make sure there's at least six to twelve inches of space around the back and sides of these displays so the heat can escape naturally. When installing outdoors, try to keep them clear from buildings or other barriers. Some installers swear by those special perforated frames because they let air circulate better between the panel and whatever surface it's mounted on.

| Clearance Type | Minimum Space | Benefit |

|---|---|---|

| Rear Panel Gap | 8 inches | Prevents heat recirculation |

| Side Clearance | 6 inches | Reduces thermal stress on adjacent panels |

Monitor Ambient Temperature and Humidity for Optimal Performance

For optimal performance, LED displays work their best magic between around 68 degrees Fahrenheit to about 86 degrees Fahrenheit, which translates roughly to 20 degrees Celsius to 30 degrees Celsius, with humidity levels ideally kept somewhere between 30 percent and 60 percent. When temperatures climb past 104 degrees Fahrenheit or 40 degrees Celsius, colors start shifting unpredictably and pixels begin to degrade faster. Humidity creeping over 70 percent can lead to unwanted moisture building up inside the display components. Putting those little IoT environmental sensors close to the screens makes sense for keeping tabs on what's happening right there in real time. Setting them up to send warnings when things get out of whack helps catch problems early. According to findings published in the 2022 LED Environmental Impact Study, companies that keep a regular eye on temperature tend to save nearly 28 percent each year on repair bills compared to those who don't monitor as closely.

Use Passive or Active Cooling Systems in High-Heat Environments

For indoor venues, passive cooling like heat sinks or thermally conductive mounting brackets effectively redistributes heat. Outdoor installations in sunny climates often require active systems:

- Axial fans (30–50 CFM) for direct airflow

- Thermostat-controlled exhaust vents to automate ventilation

- Shade structures reducing direct solar exposure by 60–80%

In desert or tropical regions, hybrid cooling systems combining airflow management and air conditioning extend panel lifespan by 3–5 years (Digital Display Report 2023). Always prioritize solutions matching your screen’s BTU output and local climate challenges.

Inspect Electrical Connections and Power Supply for Reliable Operation

Check Wiring and Connections Regularly to Prevent Signal Loss or Malfunctions

Inspect cables, connectors, and terminal blocks every quarter for signs of corrosion, loose fittings, or insulation wear. A 2023 NFPA study found 12% of LED display failures stemmed from degraded electrical components like oxidized wire terminals. For high-usage outdoor installations, increase inspection frequency during humid seasons to prevent moisture-related shorts.

Use Stable Power Sources and Avoid Voltage Fluctuations

Power inconsistencies reduce LED driver efficiency by 18% and accelerate component aging (EPRI 2024). Pair your large LED screen panels with voltage regulators or uninterruptible power supplies (UPS) in areas with frequent brownouts. Groundbreaking 2024 research on photovoltaic installations confirms stable input voltage extends semiconductor lifespan by 23% in high-wattage displays.

Install Surge Protection to Safeguard LED Screen Panels

Lightning strikes and grid transients cause 8% of permanent LED damage cases annually. UL 1449-compliant surge protection devices (SPDs) divert up to 20kA of transient current away from sensitive drivers and control boards. For multi-panel arrays, implement a tiered protection strategy:

- Primary SPDs at main power inputs

- Secondary units at distribution panels

- Tertiary modules integrated into individual screen controllers

EPRI data shows facilities with layered surge protection experience 85% fewer surge-related failures compared to unprotected systems.

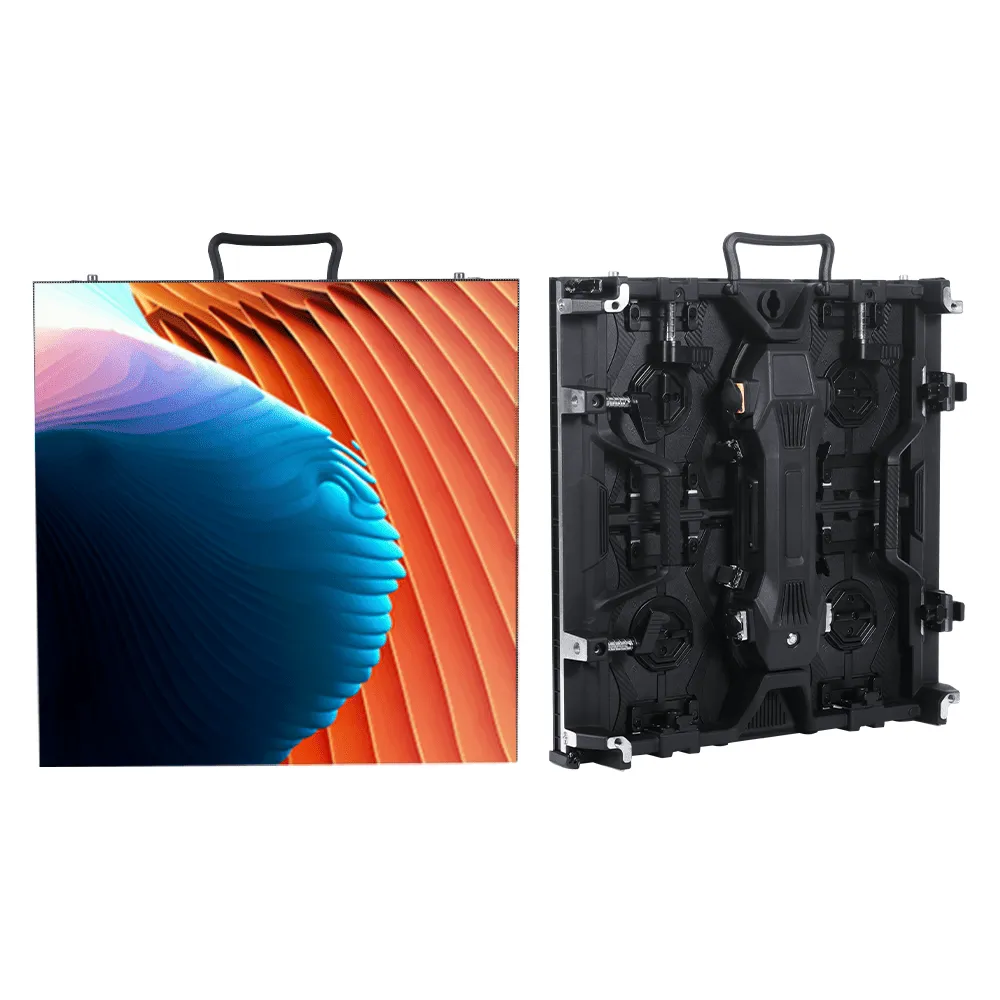

Handle and Install Large LED Screen Panels with Care to Avoid Physical Damage

Follow Safe Handling Practices During Transport and Installation

Handling large LED screens needs some care because those panels have delicate electronics inside plus glass surfaces that can crack easily. When moving them around, grab the edges with proper grips or wrap them in padding material. Stacking one panel right on top of another is a bad idea too. According to recent research published last year, almost half (about 42%) of all damage seen in the field actually comes from how people move these displays around. Most problems happen when someone jostles them while transporting or forgets to put enough cushioning between stacked panels. That kind of mishandling costs companies time and money down the road.

Avoid Direct Contact With Non-Touch LED Surfaces to Prevent Pixel Failure

The semi-permanent coating on LED display faces degrades with skin contact, oils, or pressure. Even light touches can disrupt the micro-LED array alignment, creating dead pixels within weeks of exposure. If cleaning is necessary, use manufacturer-recommended tools like anti-static brushes rather than cloths that might abrade the surface.

Use Certified Mounting Hardware for Secure and Stable Installation

Professional-grade aluminum alloy frames and UL-listed fasteners provide the structural integrity needed for multi-panel installations. Industry safety guidelines recommend load-testing mounts to 150% of the screen’s weight rating to account for wind forces in outdoor deployments. Avoid generic brackets, which lack the corrosion-resistant coatings required for humidity-prone environments.

FAQ

What is the best material to use for cleaning LED screen panels?

A soft, lint-free microfiber cloth is ideal for cleaning LED screen panels as it removes surface particles without harming the display.

How often should LED screens be cleaned?

The cleaning frequency depends on the location; busy areas may require bi-weekly cleanings, while controlled environments might suffice with monthly maintenance.

Why should harsh chemicals be avoided when cleaning LED screens?

Harsh chemicals like ammonia or acetone can damage anti-glare coatings and speed up the deterioration of protective layers.

What's the optimal brightness setting for indoor and outdoor LED screens?

For indoor screens, reducing brightness by about 30% saves energy. Outdoor screens should adjust brightness based on sunlight intensity to reduce component stress.

How can pixel degradation be prevented?

Avoid displaying static images for longer than four hours, maintain color temperature below 6500K, and use balanced display settings.

What impact does UV exposure have on LED screens?

UV exposure accelerates color fading and brittleness; using shading structures or UV-filtering films can mitigate these effects.

Why is proper ventilation important for LED screens?

Good airflow prevents overheating, extends panel lifespan, and reduces thermal stress on components.

How can voltage fluctuations impact LED screens?

Voltage inconsistencies can reduce efficiency and accelerate aging, so using voltage regulators or UPS in unstable areas is recommended.

Table of Contents

- Clean Large LED Screen Panels Regularly to Maintain Clarity and Performance

- Optimize Brightness and Display Settings to Extend LED Panel Lifespan

- Ensure Proper Ventilation and Temperature Control to Prevent Overheating

- Inspect Electrical Connections and Power Supply for Reliable Operation

- Handle and Install Large LED Screen Panels with Care to Avoid Physical Damage

-

FAQ

- What is the best material to use for cleaning LED screen panels?

- How often should LED screens be cleaned?

- Why should harsh chemicals be avoided when cleaning LED screens?

- What's the optimal brightness setting for indoor and outdoor LED screens?

- How can pixel degradation be prevented?

- What impact does UV exposure have on LED screens?

- Why is proper ventilation important for LED screens?

- How can voltage fluctuations impact LED screens?