Inti Layar papan reklame led Komponen yang Mempengaruhi Variasi Anggaran

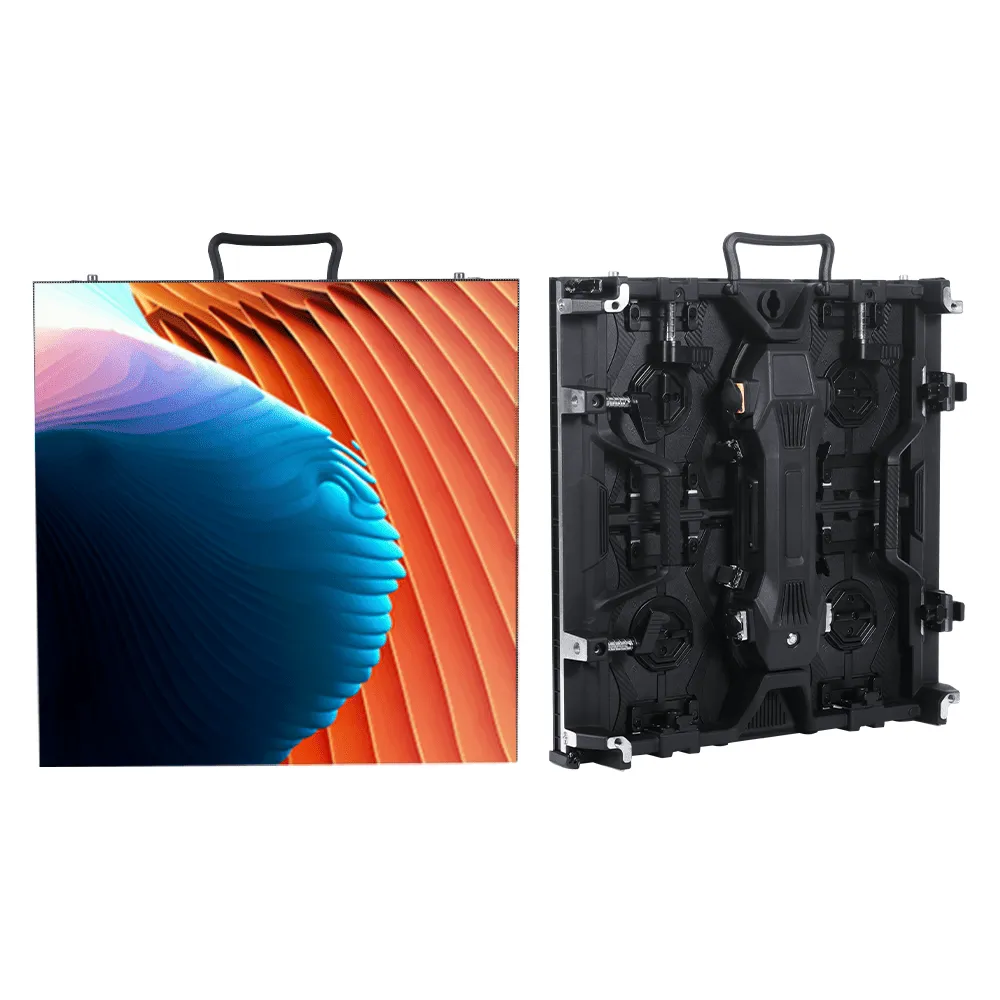

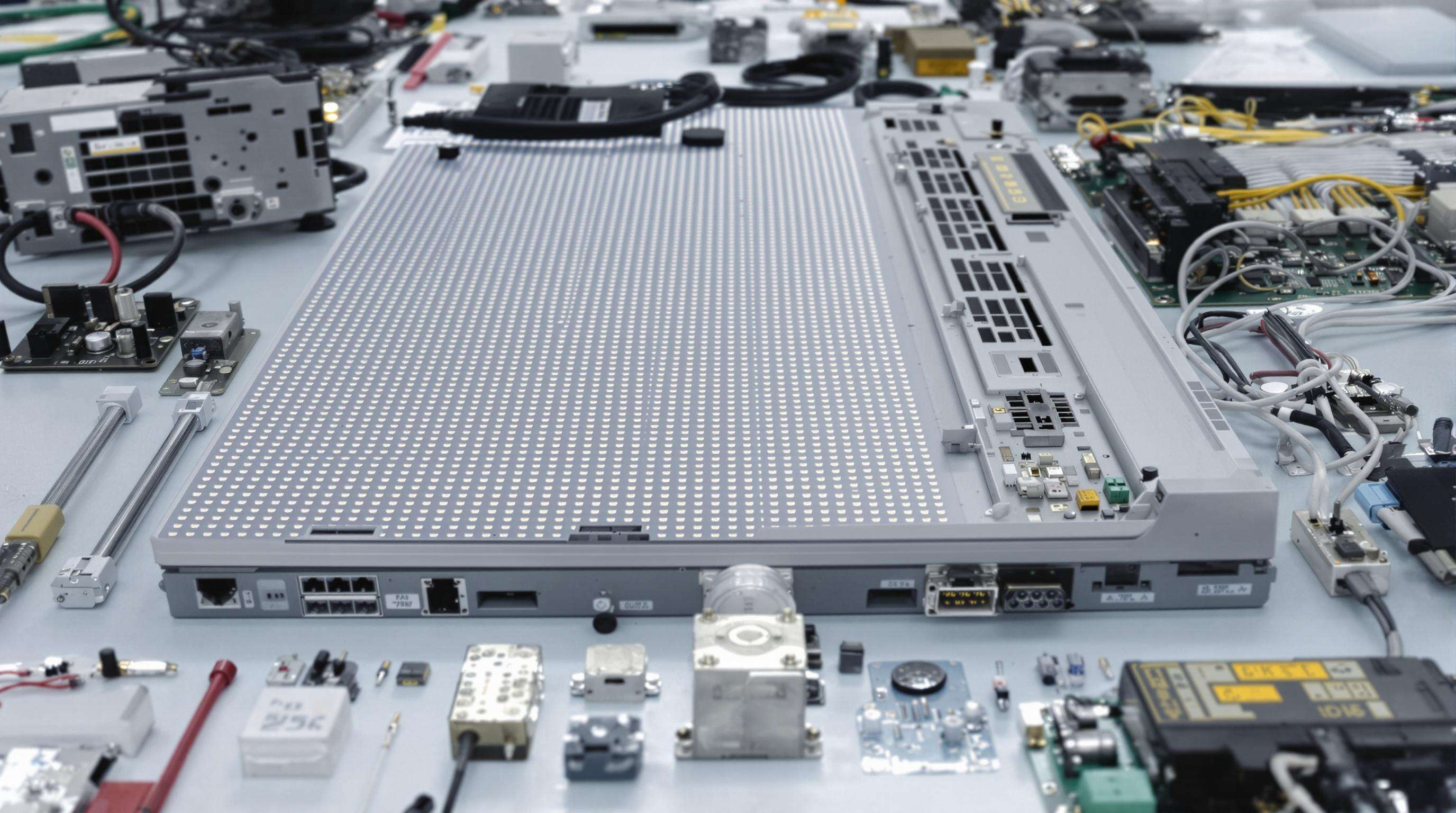

Faktor-Faktor Biaya Utama untuk Instalasi Papan Reklame LED Komponen perangkat keras utama dari papan reklame LED adalah faktor penentu bagi harganya. LED Chip dan sirkuit penggerak merupakan komponen paling mahal yang menyumbang sekitar 60% terhadap total biaya, serta menjadi sumber perbedaan harga terbesar antar berbagai jenis produk. Bahan semikonduktor berkualitas tinggi memberikan cahaya dan warna yang seragam, tetapi membutuhkan investasi awal 30-40% lebih tinggi dibandingkan bahan non-keramik. Studi industri juga menunjukkan bahwa komponen mikroelektronik ini merupakan modul dasar di mana keputusan biaya mulai berpengaruh sepanjang siklus hidup proyek.

Spesifikasi komponen memiliki pengaruh signifikan terhadap LT-OPx. LED efisiensi tinggi yang hemat daya memiliki harga tinggi, tetapi tingkat penyegaran yang lebih tinggi yang dimungkinkan oleh chip pengendali canggih dapat menjadi penting untuk area dengan lalu lintas tinggi. Di sisi lain, pemilihan komponen berdasarkan faktor harga dapat menyebabkan penurunan kecerahan lebih awal—studi menunjukkan bahwa penggunaan material berkualitas rendah dapat mengurangi usia pakai hingga 40% dalam kondisi luar ruangan. Kompromi rekayasa ini memerlukan pertimbangan hati-hati terhadap paparan lingkungan maupun pola penggunaan saat tahap spesifikasi. Kualitas catu daya, rumah pelindung, dan sistem manajemen termal menambah biaya awal, namun menghasilkan tingkat kegagalan yang lebih rendah dan frekuensi pemeliharaan yang lebih jarang selama dekade penggunaan.

Dampak Ukuran dan Resolusi terhadap Investasi Billboard LED

Metrik Pitch Piksel dan Biaya Iklan Billboard

Pixel Pitch mengontrol berapa banyak LED yang dapat muat dalam 1 meter persegi, yang dapat memengaruhi kejelasan visual Anda dan ukuran Layar LED Anda. Pitch yang lebih halus (dalam mm) menawarkan resolusi yang lebih baik untuk konten yang dilihat dari jarak dekat, seperti di zona pejalan kaki, tetapi harganya 1,5 hingga 2 kali lebih mahal dibandingkan konfigurasi P10 standar.

Kebutuhan Jarak Pandang untuk Digital Signage yang Efektif

Jarak pandang yang direkomendasikan menentukan pitch pixel yang sesuai menggunakan metrik yang disukai industri: kejelasan tampilan minimum = pitch (mm) x 1.000. Konfigurasi P8+ diperlukan untuk papan reklame di jalan tol, sehingga konten tetap terbaca dari jarak lebih dari 30 meter. Solusi yang kurang atau terlalu spesifik menghasilkan gambar yang kabur (dan ROI yang lebih rendah bagi pengiklan), sedangkan spesifikasi berlebih juga berarti biaya tambahan yang tidak perlu untuk instalasi jarak jauh seperti iklan di jalan tol.

Ekonomi Skala: Bagaimana Dimensi Mempengaruhi Biaya Produksi

Efek biaya nonlinear melalui skala relatif (baik ekonomi maupun disekonomi skala) dipicu oleh ukuran layar yang lebih besar. Dengan pembelian minimum, biaya layar LED SMD per meter persegi dapat dikurangi sebesar 18-22% untuk pesanan di atas 50m², semakin besar pesanan maka semakin besar pula penurunan biaya secara eksponensial. Ketika menyangkut layar yang lebih besar dari 100m², biaya sistem pemasangan meningkat 40% dalam aspek rekayasa (engineering) dan kompleksitas pemasangan menyebabkan biaya tenaga kerja meningkat secara signifikan meskipun produksi panel tetap efisien.

Indikator Utama Hubungan Ukuran dan Harga:

| Faktor Dimensi | Area Pengurangan Biaya | Ambang Inflasi Biaya |

|---|---|---|

| Manufaktur panel | produksi 50+ m² | Desain melengkung khusus |

| Pembelian volume LED | Batch 200 m² | Kedapairan khusus |

| Pemasangan Standar | Permukaan datar | Pemasangan tinggi/miring |

Dinamika Lokasi yang Mempengaruhi Pengeluaran untuk Layar LED

Nilai Regulasi Lalu Lintas dan Faktor yang Mempengaruhi Harga Billboard

Nilai billboard LED sangat dipengaruhi oleh lokasi, dengan lokasi “A” – dekat persimpangan jalan tol dan zona berlalu lintas tinggi lainnya – mencapai hingga 300% dari tarif iklan lokasi “B” di area yang lebih sepi. Ukuran tanda dan warna lampu biasanya diatur oleh peraturan lokal (kota), dengan anggaran terkena dampak besar akibat penerapan pembatasan ukuran tanda dan pembatasan kecerahan di kota-kota besar yang memaksa penggunaan perangkat keras yang patuh regulasi dengan biaya lebih mahal. Sebagai contoh, revisi zonasi Chicago pada 2023 mewajibkan penurunan luminansi sebesar 40% setelah pukul 11 malam, yang memerlukan pembaruan sistem kontrol per unit seharga lebih dari $15 ribu. Hambatan regulasi ini, yang juga bervariasi cukup besar tergantung lokasi, menyebabkan biaya tambahan yang secara langsung mempengaruhi tingkat investasi.

Kendala Geografis dan Biaya Perizinan

Medan yang keras dan pesisir membutuhkan rekayasa ketahanan terhadap angin/cuaca, menambahkan 18-25% harga per pemasangan dibandingkan pemasangan di wilayah perkotaan yang datar. Selain waktu, variabel utama lainnya dalam memulai operasional adalah proses pengadaan izin, yang bisa memakan waktu tiga minggu hingga 14 bulan, tergantung pada daerah setempat. Faktor geografis ini secara signifikan mengubah biaya pemasangan sebelum pekerjaan visual layar dimulai.

Spesifikasi Teknologi yang Membentuk Anggaran Layar LED

Tingkat Kecerahan dan Biaya Billboard Digital di Bawah Sinar Matahari

Billboard digital luar ruangan membutuhkan tingkat luminositas yang luar biasa untuk mengatasi silau sinar matahari, umumnya membutuhkan kecerahan 6.000 nit atau lebih dibandingkan dengan tampilan dalam ruangan yang hanya membutuhkan 1.500 nit. Premi kecerahan ini berkorelasi dengan biaya perangkat keras yang lebih tinggi sebesar 25-40% karena penggunaan chip LED khusus serta sistem pendingin yang lebih baik. Konten visual yang terlihat dengan jelas secara langsung mempengaruhi keterlibatan penonton dan metrik konversi.

Kecepatan Refresh: Kompromi antara Performa dan Biaya

Laju penyegaran yang lebih tinggi menghilangkan blur gerakan yang kritis untuk konten beraksi cepat seperti iklan olahraga, tetapi meningkatkan konsumsi daya hingga 30% dan membutuhkan modul pemrosesan premium. Iklan statis mungkin berfungsi dengan baik pada laju standar 60Hz, mengurangi pengeluaran daya tanpa mengurangi efektivitas penyampaian pesan.

Analisis Kontroversi: Fitur Premium Berlebihan di Lingkungan Statis

Debat industri mengungkapkan adanya spesifikasi berlebihan yang terus-menerus dalam pemasangan billboard berbasis teks di mana resolusi dasar sudah mencukupi. Laporan Efisiensi Digital Signage 2023 menemukan bahwa 68% tampilan teks di tepi jalan menggunakan laju penyegaran yang berlebihan tanpa peningkatan ROI yang terukur, menciptakan beban pemeliharaan dan pengeluaran finansial yang tidak perlu.

Paradoks Industri: Perlindungan Masa Depan Mempengaruhi Anggaran Jangka Pendek

Para pemasang semakin memprioritaskan komponen yang melampaui kebutuhan saat ini—seperti modul berkapasitas 4K—dengan mempertimbangkan evolusi teknologi. Pendekatan ini dapat menimbulkan premi biaya sebesar 50% tanpa nilai utilitas yang langsung terasa, menciptakan ketegangan dalam alokasi anggaran antara kompatibilitas ke depan dan kebutuhan keterjangkauan saat ini.

Kerumitan Pemasangan dalam Penyebaran Billboard Digital

Proses (OSMM) pemasangan billboard digital merupakan proses rekayasa yang kompleks, dengan logistik yang signifikan dan dapat memengaruhi anggaran awal. Variabel spesifik lokasi seperti perubahan topografi dan persyaratan beban struktural memerlukan solusi yang disesuaikan untuk struktur yang melebihi 800 inci persegi. Cara halaman diberi ketinggian dan desain pondasi membantu struktur bertahan dari kegagalan struktural, sementara analisis tanah khusus seringkali diperlukan untuk medan yang lebih rawan. Setiap proyek baru harus lolos perizinan yang ketat untuk memenuhi standar beban angin dan ketahanan gempa lokal, yang menciptakan beban waktu dan biaya tambahan.

Tuntutan Teknik Struktural untuk Proyek Berskala Besar

“Dibutuhkan banyak perhitungan teknis untuk membangun tampilan berskala besar, karena sifat fisika dari penempatan berat berbeda, begitu juga dengan kondisi lingkungan yang menegangkan. Perhitungan beban angin harus mempertimbangkan pola angin di wilayah tersebut, dan lokasi yang lebih tinggi membutuhkan tiang yang lebih kuat untuk menahan kecepatan angin di atas 120 mph. Permukaan tanah yang tidak rata memerlukan fondasi khusus—pada lokasi yang miring dibutuhkan fondasi bertingkat, yang dapat meningkatkan biaya pondasi hingga 20%. Evaluasi daya dukung perlu dilakukan untuk memastikan struktur mampu menahan beban kumulatif dari panel layar dan kerangka penopang, serta beban es dan salju di wilayah yang lebih dingin. Toleransi antar panel kurang dari 1 milimeter diperlukan pada konektor kerangka moduler untuk memastikan panel tidak melengkung.

Infrastruktur Listrik dan Variabel Biaya Tenaga Kerja

Retrofit listrik biasanya mencakup 25-40% dari biaya perangkat keras Anda, terutama saat memperbarui infrastruktur usang untuk menjalankan tampilan yang menghabiskan daya lebih dari 10.000 watt. Teknisi listrik berlisensi memiliki jendela waktu regulasi yang ketat untuk mengakses jalan, dan jendela tersebut 35% lebih sempit di pusat kota dibandingkan di pinggiran. Variasi biaya tenaga kerja menyebabkan perbedaan biaya lebih dari $50 ribu di seluruh negeri — kota-kota yang memiliki serikat pekerja rata-rata membayar $125/jam dibandingkan daerah pedesaan yang hanya $75/jam. Opsi dukungan tegangan seperti phase converter menambah biaya sekitar $8.000-$15.000 per unit, sedangkan lokasi terpencil memerlukan biaya tambahan untuk cadangan generator. Penempatan yang tepat dapat mengurangi risiko kesalahan manusia melalui penggunaan sistem tata letak digital yang dapat memangkas jam kerja hingga 15%.

Faktor Operasional Papan Reklame LED yang Mempengaruhi Biaya Total

Metrik Konsumsi Energi untuk Biaya Papan Reklame Digital

Sistem billboard LED beroperasi pada 0,3–0,8 kW/m², dan total biaya didasarkan pada harga listrik lokal, waktu dan pola penggunaan. Berbeda dengan billboard konvensional, konsumsi energi mereka menurun pada pengaturan kecerahan yang lebih rendah – pengurangan 30% dalam luminansi selama jam non-puncak menghasilkan penghematan lebih dari $1.200 per tahun untuk tampilan aspal 50 m² yang sama (Digital Signage Alliance 2023). Pelanggan yang fokus pada driver yang memenuhi kualifikasi ENERGY STAR mengalami penurunan konsumsi daya sebesar 18% dibandingkan rata-rata.

Siklus Pemeliharaan dan Biaya Penggantian Komponen

Biaya pemeliharaan sekitar 15–20% dari biaya awal setiap tahunnya untuk penggantian modul, pembaruan perangkat lunak, serta mitigasi debu/udara setiap tahun. Lingkungan yang terutama keras memperparah kondisi tersebut—untuk aplikasi di daerah pesisir, hal ini mungkin berarti penggunaan komponen tahan korosi yang harganya bisa mencapai 35% lebih mahal dibandingkan suku cadang standar. Pengendalian kondisi termal secara proaktif dapat meningkatkan usia pakai LED hingga 2–3 tahun, yang meskipun menunda biaya penggantian panel, dapat menghemat biaya sebesar $4.000–$7.000 per 10 m² per dekade.

Pertanyaan yang Sering Diajukan

Apa saja komponen utama yang memengaruhi biaya papan reklame LED?

Chip LED dan sirkuit penggerak (driver) merupakan faktor penentu biaya terbesar, menyumbang sekitar 60% dari harga keseluruhan. Bahan semikonduktor dan catu daya berkualitas tinggi turut memengaruhi harga.

Bagaimana pengaruh pitch piksel terhadap harga papan reklame LED?

Pitch piksel yang lebih halus memberikan resolusi lebih tinggi, ideal untuk jarak pandang dekat, tetapi meningkatkan biaya secara signifikan, seringkali 1,5 hingga 2 kali lebih mahal dibandingkan konfigurasi standar.

Apa dampak lokasi terhadap biaya papan reklame LED?

Lokasi mempengaruhi biaya melalui nilai iklan, persyaratan regulasi, dan tantangan geografis. Area dengan lalu lintas tinggi dan medan yang kompleks meningkatkan biaya secara signifikan.

Mengapa kecerahan penting untuk papan reklame LED luar ruangan, dan bagaimana hal itu mempengaruhi biaya?

Kecerahan tinggi sangat penting untuk mengatasi silau sinar matahari di lingkungan luar ruangan, dengan kebutuhan lumen yang lebih tinggi menyebabkan peningkatan biaya perangkat keras dan pendinginan.

Apa peran pemeliharaan dalam biaya papan reklame LED?

Biaya pemeliharaan biasanya berkisar 15–20% dari harga awal per tahun. Pemeliharaan mencakup berbagai aspek seperti penggantian komponen dan adaptasi lingkungan, terutama di iklim yang keras.

Daftar Isi

- Inti Layar papan reklame led Komponen yang Mempengaruhi Variasi Anggaran

- Dampak Ukuran dan Resolusi terhadap Investasi Billboard LED

- Dinamika Lokasi yang Mempengaruhi Pengeluaran untuk Layar LED

- Spesifikasi Teknologi yang Membentuk Anggaran Layar LED

- Kerumitan Pemasangan dalam Penyebaran Billboard Digital

- Faktor Operasional Papan Reklame LED yang Mempengaruhi Biaya Total

-

Pertanyaan yang Sering Diajukan

- Apa saja komponen utama yang memengaruhi biaya papan reklame LED?

- Bagaimana pengaruh pitch piksel terhadap harga papan reklame LED?

- Apa dampak lokasi terhadap biaya papan reklame LED?

- Mengapa kecerahan penting untuk papan reklame LED luar ruangan, dan bagaimana hal itu mempengaruhi biaya?

- Apa peran pemeliharaan dalam biaya papan reklame LED?